Helping Hillcrest Structural lower costs, improve accuracy and save time by switching from manual measuring and dumpy levels to point clouds and robotic measurements.

Based in Fareham, Hampshire, Hillcrest Structural is a steel contractor specialising in the design, supply, fabrication and erection of structural steel and ancillary systems throughout the UK. The company has its own in-house design division, production facilities and site team, a set up that enables it to offer a complete solution to its clients as well as a range of useful cross department experiences for employees.

Under the guidance of Managing Director, Jamie Green, the company also has a policy of enabling apprentices to acquire a broad knowledge of the company’s workflows following a number of placements in various Hillcrest departments. This has provided the company with fresh insights into how the implementation of new technology can bring benefits across multiple parts of the business.

In particular, this approach has highlighted the possibility of improving efficiencies on site through a range of innovative survey techniques that would directly address the challenges the site team faced during their numerous refurbishment projects.

Initiating Change

Jamie was left in no doubt about the benefits this equipment could have for his team.

Instead of relying on tape measures, dumpy levels and EDM’s, this new workflow complimented the company’s BIM Level 2 commitment. It also made best use of the steel 3D models it created with Tekla Structures software, which the company has been using for around 20 years.

With the previous workflow they created 2D drawings from the 3D Tekla model. These drawings would have to be taken onsite for mark-up using measurements taken using manual tools.

This took up an extensive amount of manhours. It needed a team of two or more and was often complicated with measurements in unreachable places. As jobs of this nature need precise information this could cause serious issues – missed points would mean a costly revisit to the site.

Jamie’s solution was to use two different methods for onsite data collection. These methods were a robotic total station with +/-2mm accuracy and a 3D laser scanner that was designed for easy adoption.

The robotic system provided a workflow that Hillcrest was already familiar with greater speed and accuracy. The 3D laser would also increase speed and reliability, alongside other benefits.

As Hillcrest are already a Trimble Tekla user, Jamie contacted KOREC to arrange a trial and demonstration. These impressed him so much that they purchased Trimble RTS773 Total Station, a Trimble X7 3D Laser scanner and a rugged T100 tablet.

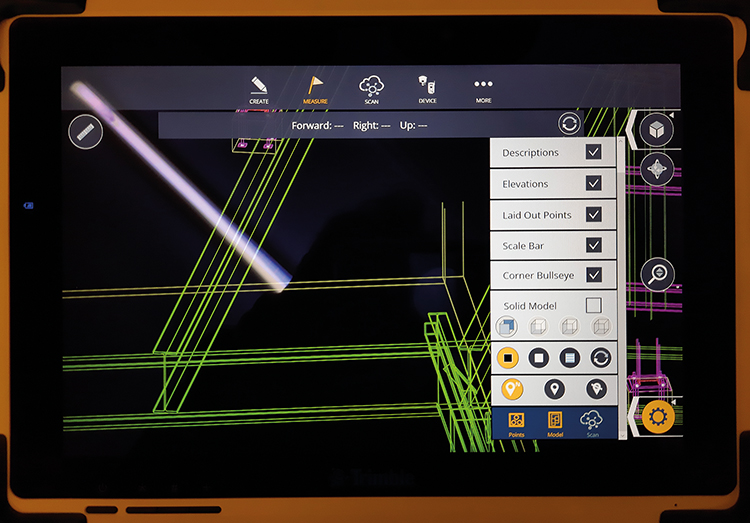

For software, they chose Trimble’s FieldLink for setting out and scanning, then the cloud-based Trimble Connect for sharing drawings and models quickly for collaborative workings.

The FieldLink software was chosen for its ability to seamlessly import IFC models, register the scans on-site and compare scans to models to detect clashes. But Jamie could see it would bring plenty of other functionality that could allow Hillcrest to grow its survey operations in the future too.

Jamie says that the combination of the Trimble RTS773, FieldLink software and the T100 tablet is a fast solution when collecting specific points of a site. It offers one man set out and reflectorless DR measuring 120m (2500m with a single prism).

A great example of this is when Hillcrest draughtsmen produce erection packages and issue them to site works. DWG files of the drawings are provided to give the setting out information for any site drilling or resin anchor locations. The site engineer will then use the RTS773 and drawings to mark out the points. This also gives an opportunity to review the layout and make sure no further enabling works are required.

This process is a lot quicker and straightforward while still being reliably accurate.

From Paper Plans to Point Clouds

Yet the most noticeable benefits come with the Trimble X7, which saves time, labour and costs.

Previously, Hillcrest had only used point clouds for visual representation purposes. Yet they saw the potential in laser scanning to optimise site surveying. Particularly when access was difficult, but also with clash detection and BIM coordination. They even felt it could help make quoting more accurate.

Hillcrest specialises in refurbishment works. This means they usually need layout dimensions and connection details for the steelwork that is already in place. In the past, this has meant significant costs to complete surveys and collect the information.

Now, their new workflow using the Trimble X7 cuts the cost of plant hire and access equipment. Instead, they can request drawings and a current IFC model built on global base points. Then, their own surveyor simply visits the site and surveys using the X7 scanner, calibrating the system to the same base point.

These scans can be registered and reviewed while the surveyor is still on site, so any gaps can be identified. This way, any missing or additional information can be collected during the same visit. No costly return trips are needed to grasp small-but-vital data.

From here, the data is sent back to the drawing office. The draughtsmen import it into 3D BIM models and overlay their survey with the planned changes. This makes the review process much quicker too.

Jamie notes how easily the survey team were able to pick up the new equipment and workflow. The RTS773, X7 and FieldLink all fitted seamlessly into the way they work.

Benefits they highlight from the X7 alone include:

- Cost reductions as they no longer need to hire tools to survey inaccessible areas

- Less time needed onsite for checks, which saves time and man hours

- Risk reduction as they can carry out as-built checks so clearly

- Simple clash detection thanks to an option in the FieldLink software

- Creates a clear visual for use in the office with clear distinctions between painted steel and concrete or encased beams

- The full visibility of the point cloud means no return to site necessary

- 3D model available for clients to refer to and keep

- Ability to import scans back into Tekla to check them against the model

“Hillcrest has an ethos of adopting new technology in order to keep competitive and ensure that our clients are getting the best possible service and value for money.

The X7, in particular, has allowed us to add value to our services and now we get requests for point clouds for a variety of purposes that we’re happy to supply! Working with groundbreaking technology such as this gives the Hillcrest team a chance to flourish and attracts a new generation of draughtsmen to the industry.

Aside from this, the technology supplied by BuildingPoint brings us some very tangible benefits. Costs are down, we have been able to reduce man hours on site and the ability to spot problems at the design stage eliminates what can be very substantial problems.

For example, on a recent job, we were able to see on the pointcloud that the line of a wall face we needed to extend was 60mm out. Because this was spotted so early, we avoided the amount of time this would have taken to put right on site, maybe around 6 extra days on the job as well as a huge knock-on effect for the trades that follow us.

We also have complete confidence in the data. When working on a London project we needed to ensure that RHS beams of 18-19m in length would fit exactly to the faces of precast steel plates within a concrete wall.

For the weld to take we were working with accuracies of just 1mm tolerance. Previously, this would have been a very long-winded process and using a tape measure could result in discrepancies over this distance. With the X7 it took literally minutes! In this case, because the instrument was new to us, we also checked measurements with an EDM which took around 4 hours. The X7 was spot on!”

– Jamie Green, Hillcrest Managing Director

Thanks to Jamie and Hillcrest Design Technician, Jay White, for supplying the information for this case study.

Write a Comment